Lean Methodology: A Product Coach's Guide to Eliminating Waste

Lean methodology is a systematic approach to eliminating waste and maximizing customer value. Originating from Toyota's manufacturing system and later adapted for software through Eric Ries's Lean Startup, lean methodology has become the foundation for how modern product teams build, measure, and learn. In my coaching experience, the teams that struggle most with lean are the ones that treat it as a set of tools rather than a way of thinking.

This guide covers lean methodology through the lens of product coaching: not the factory-floor version you find in textbooks, but the practical version that helps product managers, designers, and engineers deliver more value with less waste.

TL;DR: Lean Methodology in 60 Seconds

- Core idea: Eliminate waste, maximize customer value, and learn continuously

- 5 principles: Define Value, Map the Value Stream, Create Flow, Establish Pull, Pursue Perfection

- Product teams: Build-Measure-Learn replaces Plan-Build-Ship. MVPs are learning tools, not half-baked products

- Key metric: How fast can your team go from hypothesis to validated learning?

- Bottom line: Lean is a mindset, not a checklist. It works when teams internalize the principles, not when they follow the motions

What Is Lean Methodology?

Lean methodology is a management philosophy focused on creating maximum value for customers while minimizing waste. It originated at Toyota in the 1950s, where Taiichi Ohno developed the Toyota Production System (TPS) to compete with American automakers despite having far fewer resources. The core insight was simple: instead of making more, make better. Instead of working harder, eliminate the work that does not create value.

In 2011, Eric Ries published "The Lean Startup," translating Toyota's manufacturing principles into a framework for building products under uncertainty. This shift brought lean thinking into the world of software, product management, and digital product development. Today, lean methodology guides everything from startup MVPs to enterprise product portfolios.

For product teams, lean methodology answers a critical question: how do you build the right thing without wasting time building the wrong thing? The answer involves understanding waste, establishing feedback loops, and making decisions based on evidence rather than assumptions.

"There's nothing so useless as doing efficiently that which should not be done at all." (Rich Mironov, Product Management veteran with 30+ years experience)

That quote captures the essence of lean thinking for product teams. Efficiency without effectiveness is just organized waste. According to the Standish Group's CHAOS report, only 35% of software features are used regularly. That means 65% of what product teams build creates little or no value. Lean methodology exists to close that gap.

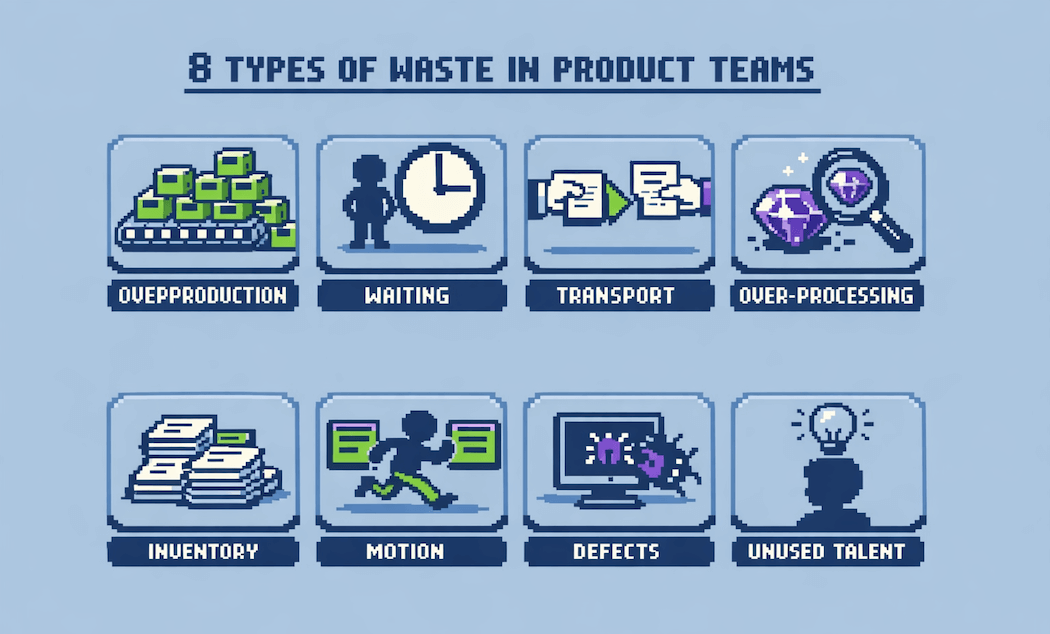

The 8 Types of Waste in Product Development

Toyota identified seven types of manufacturing waste (muda). For product teams, these translate into digital equivalents that are equally destructive:

| Manufacturing Waste | Product Team Equivalent | Example |

|---|---|---|

| Overproduction | Feature bloat | Building features nobody requested or validated |

| Waiting | Handoff delays | Design waiting for specs, engineering waiting for designs |

| Transportation | Task switching | Context-switching between 5 projects instead of focusing on 1 |

| Over-processing | Gold-plating | Perfecting a feature before validating the concept |

| Inventory | Unshipped work | Features completed but not released to users |

| Motion | Unnecessary meetings | Status updates that could be async messages |

| Defects | Rework | Building, shipping, then rebuilding because requirements were wrong |

| Unused talent | Underutilized expertise | Senior engineers doing ticket admin instead of architecture |

When I work with teams adopting lean for the first time, the biggest resistance comes from acknowledging how much waste already exists. Nobody likes hearing that 60% of their sprint is non-value-adding activity. But recognizing the waste is the first step to eliminating it.

The 5 Lean Principles for Product Teams

James Womack and Daniel Jones codified five lean principles in their 1996 book "Lean Thinking." These principles were designed for manufacturing, but they translate directly to product development strategy when adapted thoughtfully.

Principle 1: Define Value

Value is defined by the customer, not by the team. This sounds obvious, but most product teams define value internally. They build features because stakeholders requested them, because competitors have them, or because engineers find them interesting. Lean starts by asking: what does the customer actually need?

"Strategy by definition is choosing what not to do." (Christian Idiodi, Partner at Silicon Valley Product Group)

Defining value means choosing what not to build. Every feature you say "no" to is waste you prevented. The best product teams I coach spend more time validating whether something should be built than actually building it. This connects directly to running product discovery before committing engineering resources.

Principle 2: Map the Value Stream

A value stream is every step required to deliver value from idea to customer. In product development, this includes discovery, design, development, testing, deployment, and feedback collection. Mapping it reveals where waste hides.

Common findings when teams map their value streams: a feature idea takes 6 weeks from concept to production, but only 12 hours of that is actual development. The rest is waiting: waiting for approval, waiting for design, waiting for code review, waiting for deployment windows. Lean methodology targets those gaps.

Principle 3: Create Flow

Once you have mapped the value stream, eliminate bottlenecks so work flows smoothly. In product teams, flow means reducing handoffs, automating repetitive steps, and ensuring teams have everything they need to complete work without interruption.

The enemy of flow is batch processing: collecting requirements in large documents, designing all screens before any development starts, or releasing software in quarterly mega-releases. Lean prefers small batches. Smaller work items move faster through the system and provide faster feedback.

Principle 4: Establish Pull

Pull means starting work only when there is demand for it. In manufacturing, this means producing only what customers order. In product development, pull means building only what validated customer needs require.

The opposite of pull is push: filling the backlog with speculative features, building a roadmap based on executive opinions, or shipping features because "the competitor has it." Pull-based product development starts with evidence of customer need and pulls work through the system based on that evidence.

Principle 5: Pursue Perfection

Perfection in lean does not mean building a flawless product. It means continuously improving the process of creating value. Every sprint retrospective, every post-mortem, every customer feedback session is an opportunity to eliminate more waste and deliver more value.

This principle is often called "kaizen" (continuous improvement). It is not a one-time initiative. It is a permanent mindset. The best teams I coach never stop asking: "Where is the waste?" and "How can we deliver value faster?"

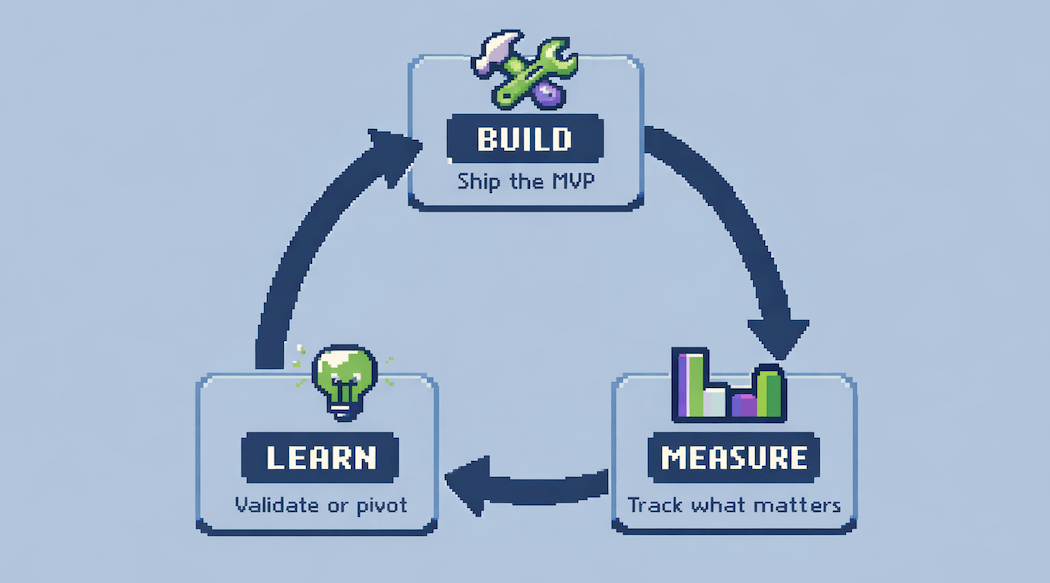

Build-Measure-Learn: The Engine of Lean Product Development

Eric Ries introduced the Build-Measure-Learn cycle as the core operating loop for lean product development. It replaces the traditional Plan-Build-Ship approach with a learning-centered cycle that minimizes wasted effort.

The cycle works in reverse order from how most people read it. You start with what you want to Learn, then figure out what to Measure to validate that learning, then determine the minimum thing to Build to generate those measurements. This inversion is critical. Most teams start by building something cool, then figure out how to measure it, then try to learn something from the data. That sequence maximizes waste.

The MVP as Learning Tool

The minimum viable product is the most misunderstood concept in lean methodology. An MVP is not a crappy version 1.0. It is the smallest thing you can build to learn the next most important thing.

"It's not an experiment if you're not willing to kill the idea." (Josh Seiden, co-author of Lean UX)

That willingness to kill ideas is what separates lean teams from traditional teams. An MVP that proves the hypothesis wrong is a success. It prevented months of wasted development. The teams I coach who struggle with MVPs are usually the ones who cannot emotionally detach from their ideas. They build MVPs hoping to confirm their assumptions rather than genuinely testing them.

A practical example: I coached a B2B SaaS team that wanted to build an AI-powered analytics dashboard. Instead of spending 6 months building the full product, they created a spreadsheet with manual analysis for 10 pilot customers. Within 3 weeks, they learned that customers cared about 2 of their planned 8 features. They saved 4 months of engineering time by learning what not to build. That is lean methodology in practice. You can track these learning cycles using lean analytics principles to measure what actually matters at each stage.

Lean vs Agile vs Scrum: How They Connect

Lean, Agile, and Scrum are often used interchangeably, but they operate at different levels. Understanding their relationship helps teams implement each one more effectively.

| Dimension | Lean | Agile | Scrum |

|---|---|---|---|

| Level | Philosophy | Mindset | Framework |

| Focus | Eliminate waste, maximize value | Respond to change, deliver iteratively | Sprint-based delivery with defined roles |

| Origin | Toyota (1950s) | Agile Manifesto (2001) | Schwaber & Sutherland (1995) |

| Key question | "Are we building the right thing?" | "Are we building it the right way?" | "How do we organize the work?" |

| Cadence | Continuous | Iterative | Fixed sprints (1-4 weeks) |

| Metrics | Cycle time, waste ratio, value delivered | Working software, customer satisfaction | Velocity, sprint burndown |

| Scope | Entire organization | Development team + stakeholders | Single team |

The pattern I see across startups and scale-ups: lean methodology only sticks when leadership models the behavior. You cannot ask teams to eliminate waste while leadership piles on pet projects. You cannot ask teams to validate before building while executives demand features by arbitrary deadlines.

In practice, the most effective teams combine all three. Lean provides the strategic thinking (build the right thing). Agile provides the development philosophy (build it iteratively). Scrum and Kanban provide the tactical framework (organize the daily work). Teams that understand lean principles implement Scrum and Kanban more effectively because they know why the practices exist, not just how to follow them.

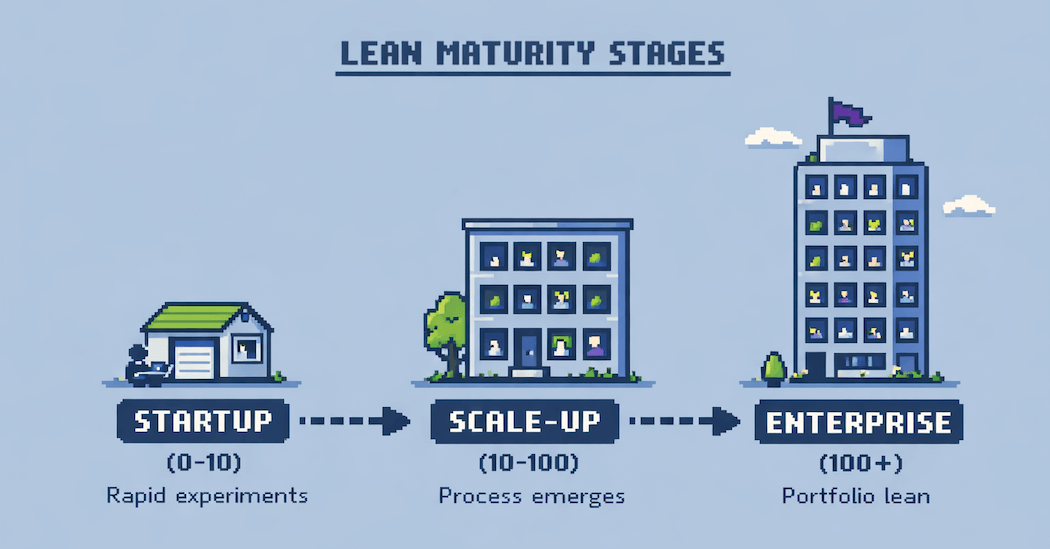

What Lean Looks Like at Different Stages

Lean methodology is not one-size-fits-all. How you apply it depends on your company's stage, team size, and market context.

Startup (0-10 people)

At the startup stage, lean is survival. You have limited resources, limited time, and unlimited uncertainty. The Build-Measure-Learn cycle runs at maximum speed. MVPs are your primary tool. Every decision is a bet, and lean methodology helps you make smaller, cheaper bets.

Key lean practices at this stage: customer interviews before writing any code, landing page tests before building products, concierge MVPs (manual service before automation), and weekly pivot-or-persevere decisions. The goal is to find product-market fit as fast as possible while burning as little cash as possible.

Scale-up (10-100 people)

When lean gets hard. The informal processes that worked with 8 people break down with 40. Value stream mapping becomes essential as handoffs multiply. WIP limits prevent the team from drowning in parallel initiatives. Regular retrospectives formalize the continuous improvement that happened naturally in a small team.

The biggest lean challenge at this stage is maintaining speed. Startups can validate an idea in a week. Scale-ups often take months because of approval layers, coordination overhead, and the fear of breaking what already works. Lean thinking at this stage means fighting organizational bloat before it calcifies.

Enterprise (100+ people)

At enterprise scale, lean becomes about portfolio management. Which products deserve investment? Which should be sunset? How do you balance exploitation (optimizing existing products) with exploration (finding new opportunities)?

Enterprise lean also involves cultural resistance. Teams that have operated in plan-driven, waterfall environments for decades will not adopt lean overnight. The pattern I see in enterprise coaching: successful lean transformations start with one team, prove results, then spread organically. Top-down mandates create compliance without conviction.

5 Lean Mistakes I See in Coaching

After years of coaching product teams through lean adoption, these are the mistakes I encounter most frequently.

Mistake 1: Treating Lean as Cost-Cutting

Lean is about maximizing value, not minimizing cost. When leadership frames lean as "do more with less," teams hear "we are cutting your resources." Real lean thinking asks: "How do we deliver more value?" Sometimes that means investing more in the right areas while cutting waste in others. A team that eliminates three unnecessary approval steps is not cutting costs. They are accelerating value delivery.

Mistake 2: Skipping the "Learn" in Build-Measure-Learn

Many teams build MVPs and collect data but never change course based on what they learn. They treat the cycle as Build-Measure-Build-More. If your MVP shows the hypothesis was wrong but you build the full product anyway, you are not doing lean. You are doing waterfall with a prototype step.

Mistake 3: Applying Manufacturing Lean Literally to Software

Software is not a factory. You cannot stamp out identical units. Knowledge work has fundamentally different properties: variability is the norm, creativity matters, and the "product" is intangible. Teams that try to apply manufacturing lean tools directly (like Six Sigma's statistical process control) to software development create overhead without benefit. Adapt the principles, not the specific tools.

Mistake 4: Lean as Permission to Ship Incomplete Work

"We are being lean" is not an excuse for shipping garbage. An MVP is the minimum viable product, emphasis on viable. It must solve a real problem for real users, even if the solution is minimal. A landing page with no product behind it is a validation test, not an MVP. A half-working feature with critical bugs is not lean. It is sloppy.

Mistake 5: Ignoring "Respect for People"

Toyota's lean system has two pillars: continuous improvement and respect for people. Most western adoptions of lean focus exclusively on process improvement and ignore the human element. Lean teams need psychological safety to flag waste, authority to fix problems at their source, and trust from leadership to experiment and occasionally fail. Without respect for people, lean becomes a management tool wielded against teams rather than a mindset teams embrace.

Getting Started with Lean Methodology

You do not need a transformation initiative to start applying lean thinking. Here is a three-week pilot that any product team can run:

Week 1: Map Your Value Stream

Take one recent feature from idea to production. Draw every step on a whiteboard. For each step, note: how long did it take? How long was it waiting between steps? How many people touched it? How many handoffs occurred? You will likely discover that 80% of the elapsed time was waiting, not working.

Week 2: Identify Your Biggest Waste

From your value stream map, identify the single largest source of waste. Is it handoff delays? Rework from unclear requirements? Features built that users did not want? Pick the one that wastes the most time or creates the most frustration. Do not try to fix everything at once.

Week 3: Run One Experiment

Design a small experiment to reduce that waste. If handoff delays are the problem, try co-locating design and engineering for one sprint. If rework is the problem, add a 30-minute discovery session before sprint planning. Measure the result. Did cycle time improve? Did rework decrease? Use the data to decide whether to continue, adjust, or try something different.

This three-week approach is lean methodology applied to lean adoption: small batches, fast feedback, evidence-based decisions. If your team wants structured guidance through this process, my product coaching services help teams implement lean principles that fit their specific context, whether you are a startup finding product-market fit or a scale-up fighting organizational waste.

Conclusion

Lean methodology is not a project with a start and end date. It is an ongoing practice of questioning assumptions, eliminating waste, and delivering value faster. The five principles (Value, Value Stream, Flow, Pull, Perfection) provide the framework. Build-Measure-Learn provides the operating rhythm. But the real work happens in the daily decisions: choosing what not to build, killing ideas that data does not support, and investing in learning before investing in development.

Start small. Map one value stream. Identify one source of waste. Run one experiment. Learn from the result. That single cycle will teach you more about lean methodology than any book or certification. The teams that succeed with lean are not the ones that implement it perfectly from day one. They are the ones that commit to improving every week, every sprint, and every quarter.